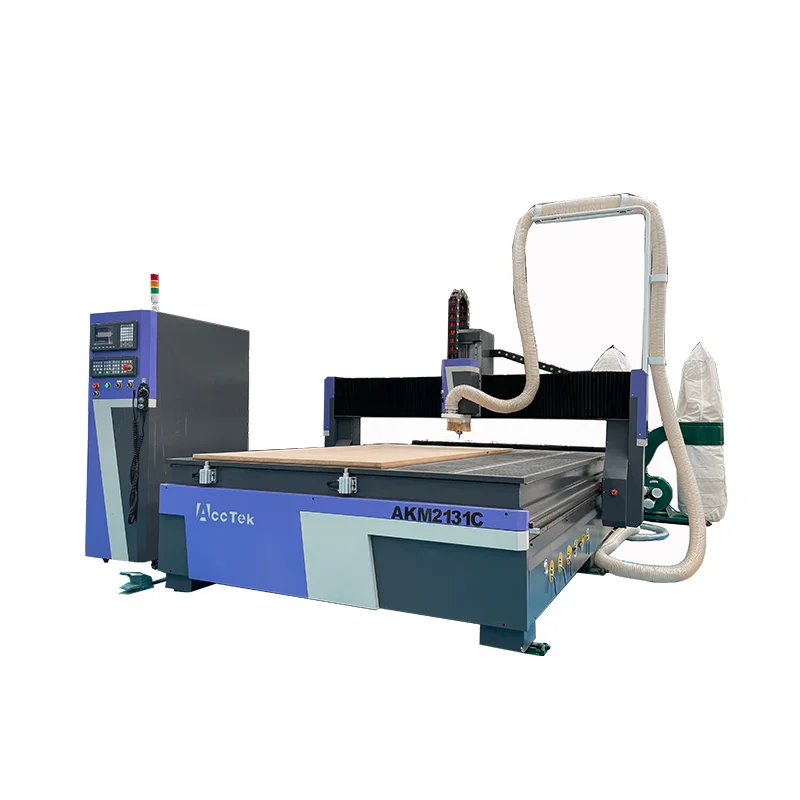

Jinan Cnc Router Mdf Atc 2131 9.0Kw Air Cooling | Инструменты

Сохраните в закладки:

История цены

*История изменения цены! Указанная стоимость возможно, уже изменилось. Проверить текущую цену - >

| Месяц | Минимальная цена | Макс. стоимость | Цена |

|---|---|---|---|

| Sep-16-2025 | 449006.11 руб. | 471456.73 руб. | 460231 руб. |

| Aug-16-2025 | 445233.63 руб. | 467495.85 руб. | 456364 руб. |

| Jul-16-2025 | 373543.34 руб. | 392220.27 руб. | 382881.5 руб. |

| Jun-16-2025 | 437687.22 руб. | 459571.72 руб. | 448629 руб. |

| May-16-2025 | 381089.59 руб. | 400143.72 руб. | 390616 руб. |

| Apr-16-2025 | 430140.92 руб. | 451647.19 руб. | 440893.5 руб. |

| Mar-16-2025 | 426367.37 руб. | 447685.1 руб. | 437026 руб. |

| Feb-16-2025 | 422594.9 руб. | 443724.90 руб. | 433159 руб. |

| Jan-16-2025 | 418821.26 руб. | 439762.20 руб. | 429291.5 руб. |

Новые товары

Автофокусирующаяся мини портативная оптическая волоконная лазерная маркировочная машина из нержавеющей стали/алюминия/ПВХ/АБС/кольцевых украшений/металла для ювелирных изделий 20 Вт.

Четырехшпиндельный станок с ЧПУ Blue Elephant для автоматической 3D-резьбы по дереву Furniture 1325.

Станок для плазменной резки металлов 1530 200A китайского производства, с ЧПУ, настольный, 63A 100A 120A.

Восьмишпиндельный деревообрабатывающий станок с ЧПУ, мультиротарным столом и одной головкой, толщина стали 8 мм, модель 1730 для производства ремесел.

Лазерная резка нержавеющей стали на плоских и трубчатых заготовках 10 мм.

Автоматическая режущая машина для кожи ковриков для автомобилей с установленными на ней Kwang Yeow (Taiwan) квадратными линейными направляющими.

Набор для модернизации оси X CNC 3018 Pro подходит для роутера.

3d деревообрабатывающая резьба ATC фрезерный станок с ЧПУ/kichen gabinet гравировка

Характеристики

Jinan Cnc Router Mdf Atc 2131 9.0Kw Air Cooling | Инструменты

Описание товара

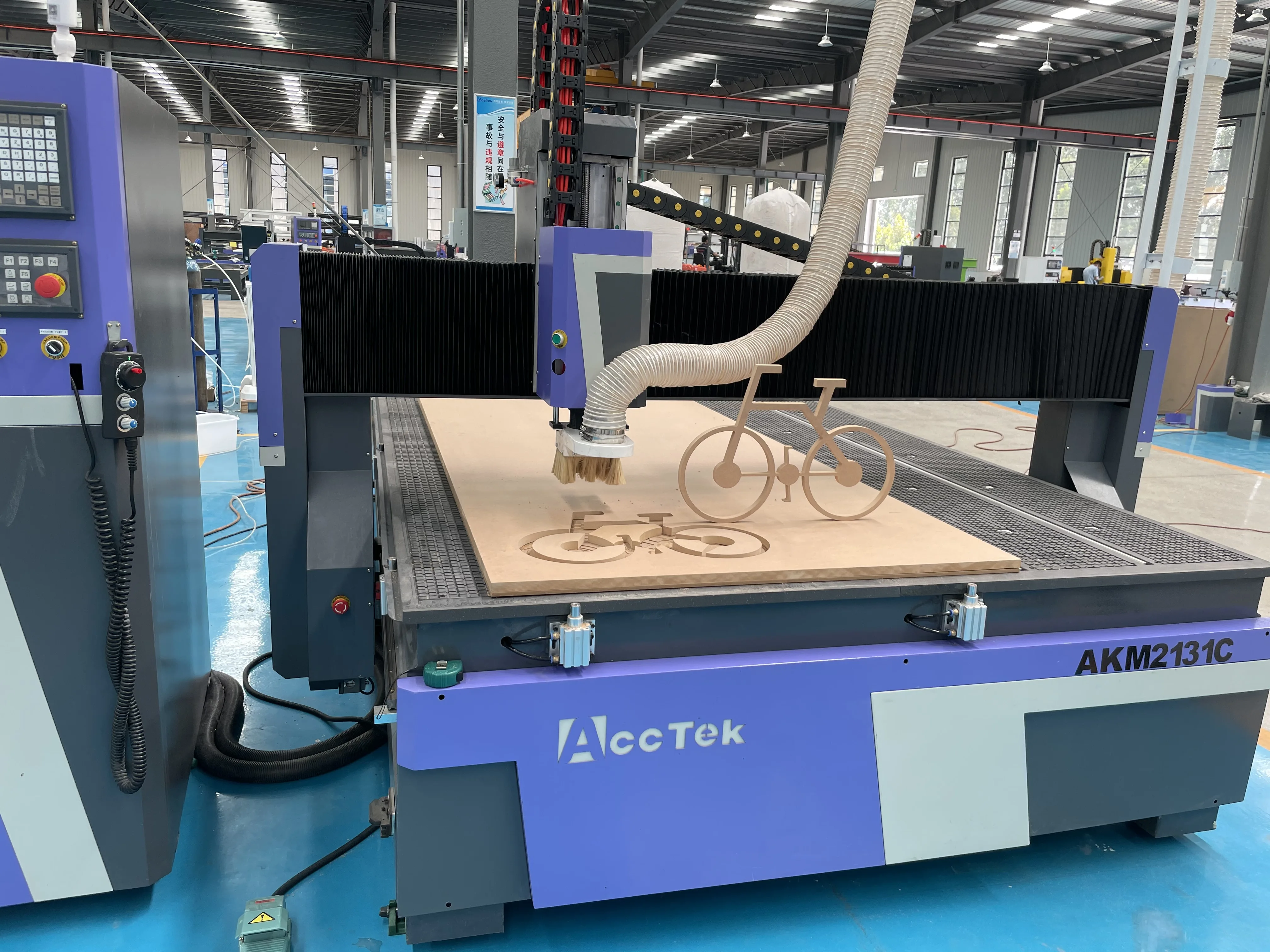

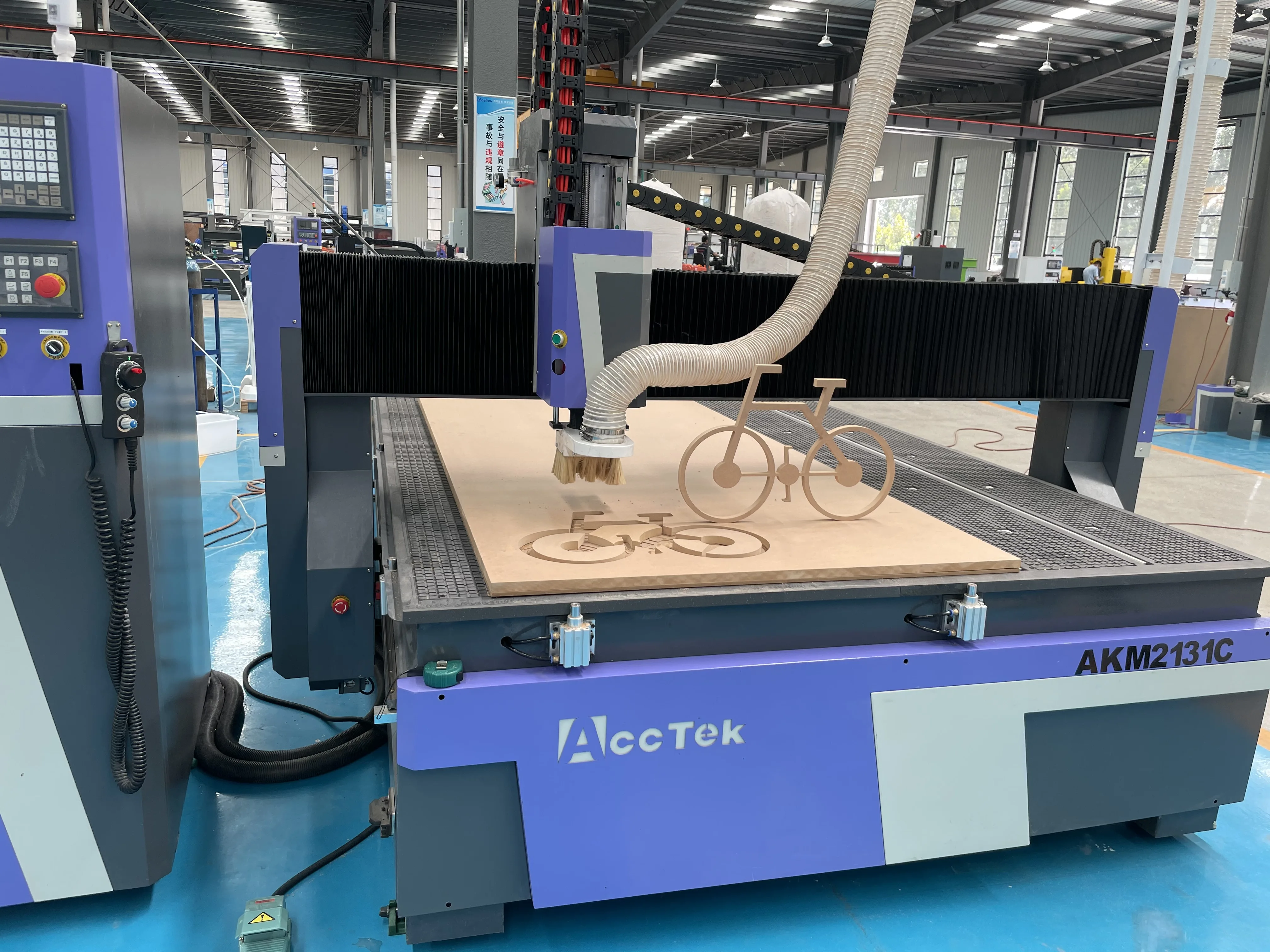

Advantages of AKM2131C1. The whole machine adopts seamless welding of steel structure, with strong bearing capacity and small deformation. Linear square rail, high precision, wear resistance and stable operation.

Advantages of AKM2131C1. The whole machine adopts seamless welding of steel structure, with strong bearing capacity and small deformation. Linear square rail, high precision, wear resistance and stable operation.2. Adopt linear, disc or follow-type automatic tool change system, the tool change time only needs ten seconds, which saves tool change time and improves production efficiency.

3. Split keyboard operation: concise, convenient and easy to learn. Users can quickly and flexibly master the use of equipment,with greater independence.

4. Syntec control system. The intelligent processing cross-border protection function prevents mechanical collisions caused by the design layout exceeding the processing range. Intelligent processing speed control can control the processing speed separately, improve processing efficiency, extend tool life, and increase yield.

5. File preprocessing function helps users correct errors in processing files in time, and is well compatible with processing codes generated by Type3/Artcam/Aspire/Solidworks etc. The three-dimensional curve prediction algorithm, the broken line is stable, to ensure the speed and accuracy of the curve.

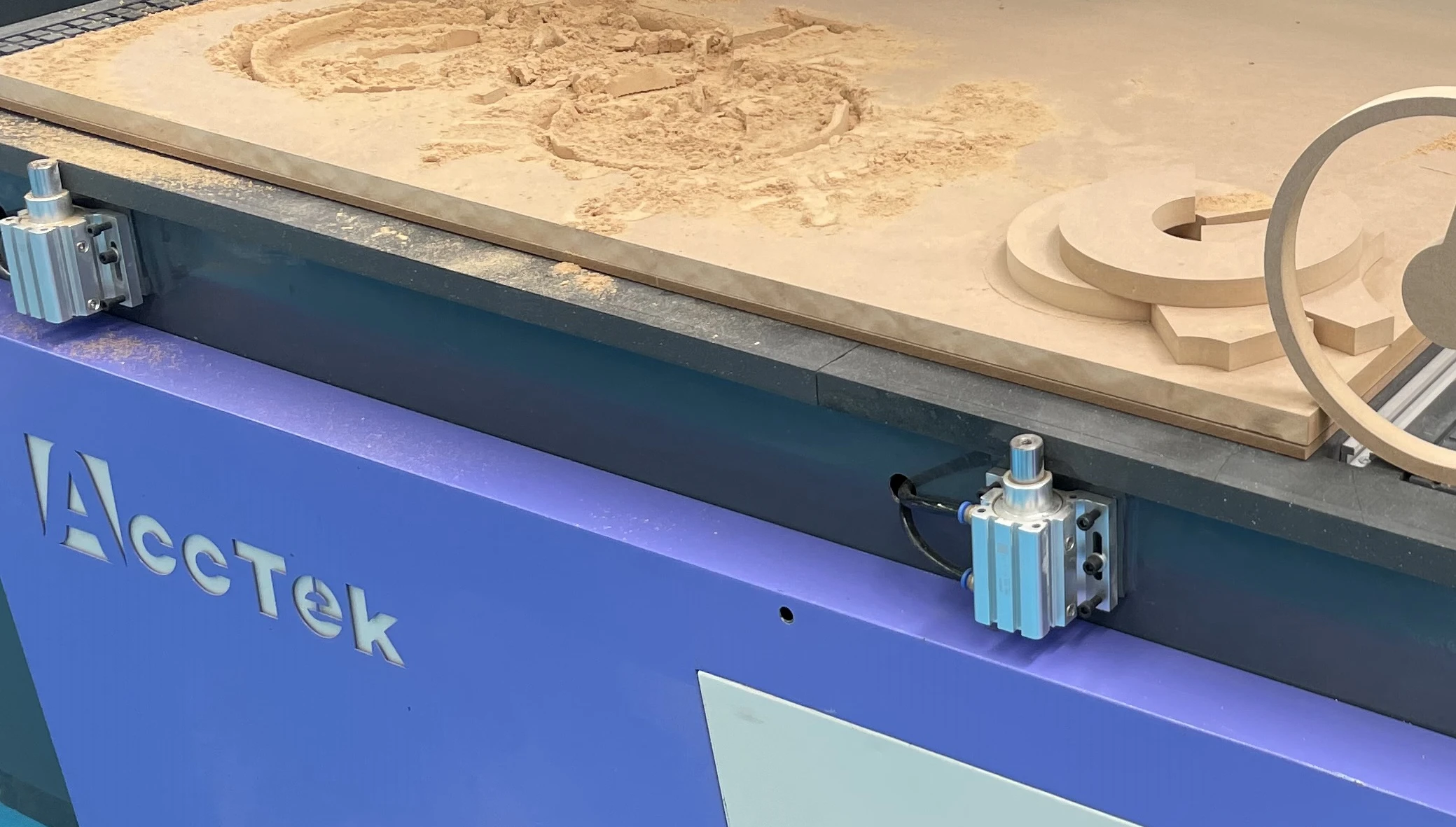

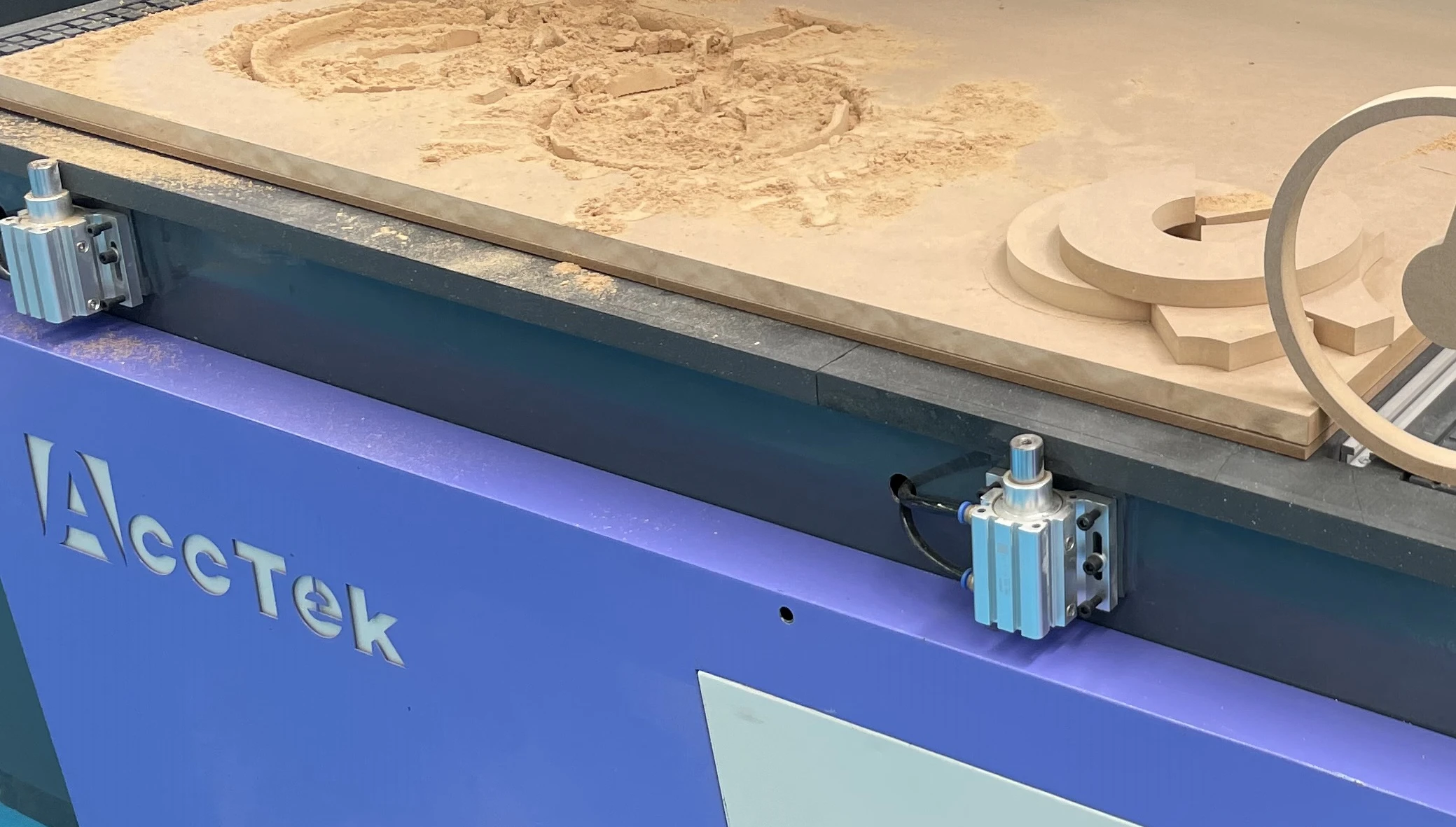

6. Dust collection and adsorption device: The dust collection system can absorb wood chips and debris during the processing process, and maintain the equipment in disguised form to keep the workbench

clean; the six-zone vacuum adsorption table can be used for adsorption of different sizes of plates instead of The mechanical plate fixing in the past has shortened the loading and unloading time of the plate outside of processing.

SpecificationDescriptionParameterX,Y Working Area2100*3100*250mmZ Working Area250mmResolution0.01mmLathe StructureSeamless welded steel structure, better than cast iron oneX,Y StructureRack and pinion, gear drive,

Taiwan 25mm square guide railsZ StructureTAIWAN TBI rolling ball screw,

Taiwan 25mm square guide railsMax. Idling Speed55m/minSpindle9.0kwSpindle Speed0-18000r/min, variable speedWorking VoltageAC220V,1PH or 220V/380V,3PH, 50/60HzMotor and driverservo motor and driversWorking ModeSERVOCommandG code (HPGL,U00,mmg,plt)Operating SystemSyntecDiameter of Cutterφ3.175-φ22Cooling ModeAir-coolingDust-collect FunctionYesWork HoldingVacuum with t slotTool Magazine8-slot Tool Magazine with 8 ISO 30 toolsNet Weight2050KGNet Weight1900KGConfiguration

9kw ATC air cooling spindlestrong power, can be widely used for different thickness materials, international famous brand, good using.Smooth body, not easy to rust; powerful and longer lifetime.

Independent research and development, rational design.Taiwan Syntec controller systemThe intelligent processing cross-border protection function prevents mechanical collisions caused by the design layout exceeding the processing range. Intelligent processing speed control can control the processing speed separately, improve processing efficiency, extend tool life, and increase yield.

Servo motor

Faster speed with signal feedback .Low heat radiation .Run smoothly at ultra-low speed.Reduce the vibration ,avoid oscillation . Efficient torque enhancement .

Dust proof structure

protect mechanical parts better, prolong lifetime.

Cylinder positioning pop pins.Cylinder positioning pop pins.(2 on X axis, 3 on Y axis)Application

Woodworking industry:

solid wood furniture, custom furniture, furniture decoration, musical instrument manufacturing, wooden handicrafts, art models, artistic font characters, logos, plate plane carving, artistic murals, screen relief carving and cutting, decoration processing, gift packaging, wave boards, Cutting the three-dimensional surface and shape of various wooden industrial

products such as electrical appliances, sporting goods, etc.

Mold industry: It can engrave various molds, wooden molds, fonts, aviation wooden molds, propellers, building models, sand table

models, motorboat models, automobile foam molds, etc.

◆ Plate processing: insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti bate

board,epoxy resin, ABS, PP, PE and other carbon mixed compounds.

◆ Decorate industry: Acrylic, PVC, MDF, artificial stone, organic glass, plastic and soft metals such as copper, aluminum plate

engraving and milling process.

.◆ Craft & gift industry: engrave various word or graph on the souvenir and handicraft, ironwork engraving, dials.

◆ Advertising industry: engrave and cut various signboards, marble, copper, character mold, font. And various metal sign, brand.

Customers feedback

Customers feedback Quality Control

Quality Control FAQQ1:Are you manufacturer ? Yes,We are factory since 2005.

FAQQ1:Are you manufacturer ? Yes,We are factory since 2005.Q2: How can I get an accurate price?

Please tell us your cutting material and the working size.

Q3: How is your after sales service?

Our sales service team are online for 24-hours. We can also supply overseas install service.

Q4: How long is the delivery time?

Generally 7 ~ 15 days.

Q5: Can I get a machine according to my own requirements?

Sure.We accept OEM and ODM

Q6: If my machine is broken. Can you repair it for me?

Yes. We have free training online. If there is big trouble with your machine in the warranty time, we can help you repair it.

Q7: How is the quality of your machine?

Our machine adopts heavy lathe bed, and each part is processed by CNC machining center, which greatly improves the accuracy of

machine operation.

Q8: What’s your MOQ and delivery?

1 set by LCL.

3~9 sets by containerOur Factory

Трекер стоимости

Отзывы покупателей

Новые отзывы о товарах

Заказывала парку через этот сайт, случайно на него наткнулась в интернете! Доставка очень быстрая, даже не ожидала, не приходится... Читать отзыв полностью...

Решил заказать для своей дочки платье на Новый Год. Приглянулось данный товар. Доставку ждал около трех месяцев, главное, что пришел... Читать отзыв полностью...

Отличная обувь.размер подошёл. Носится отлично. Качество хорошее . Буду заказывать ещё. Спасибо за ботиночки.а цена вообще просто бомба. Вообще очень... Читать отзыв полностью...

Использую DBPOWER 4K с 2016 года. Аккумуляторные батареи вышли из строя. Сообщите их обозначение для заказа и где купить.... Читать отзыв полностью...

Добрый день! Заказывала блузку через сайт alisalebay.ru.Меня удивила очень быстрая доставка, я не ждала полтора месяца, как это обычно... Читать отзыв полностью...

Второй раз заказываем с АлиЭкспресс, через этот сайт. Доставкой довольна,быстро и во время. На счёт халатов просто нет слов,заказали со... Читать отзыв полностью...

Заказал сыну данный рюкзак, он показался мне практичным. Доставка была достаточно долгая где-то четыре месяца. Сам товар удобный, много помещается... Читать отзыв полностью...